Power Generated By Steam

The Childs and Irving power plants were hydroelectric. Meaning they were creating energy from the water flow at Fossil Creek. Whereas TAPCO used water from the Verde River to create steam. Steam power works by super heating water into steam through the use of boilers that are operated by burning any number of fuels, TAPCO used crude oil that was delivered by rail.

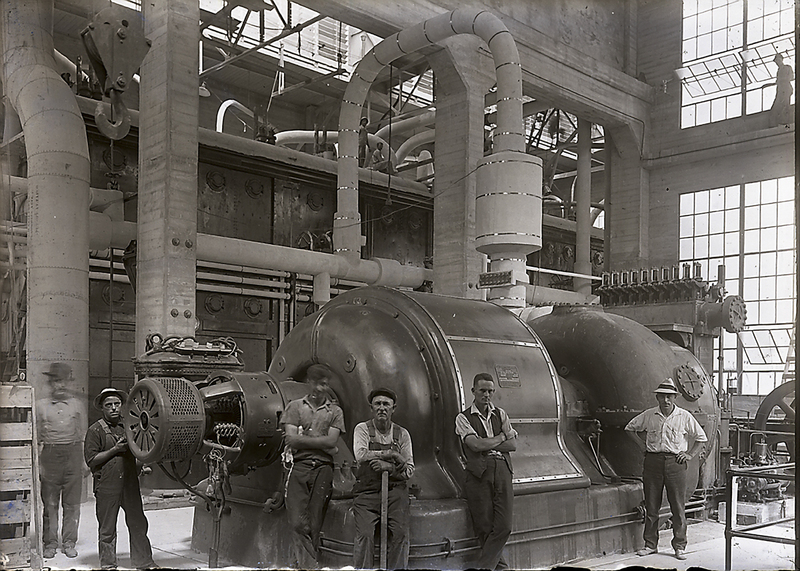

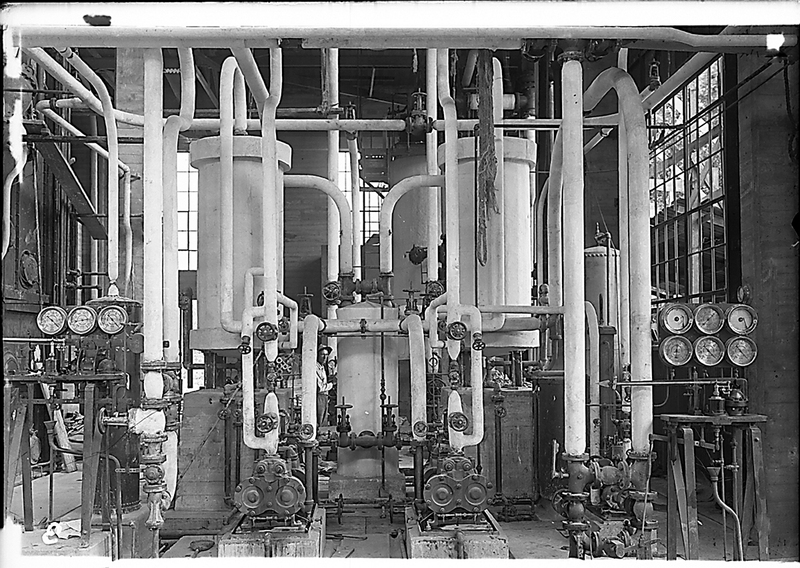

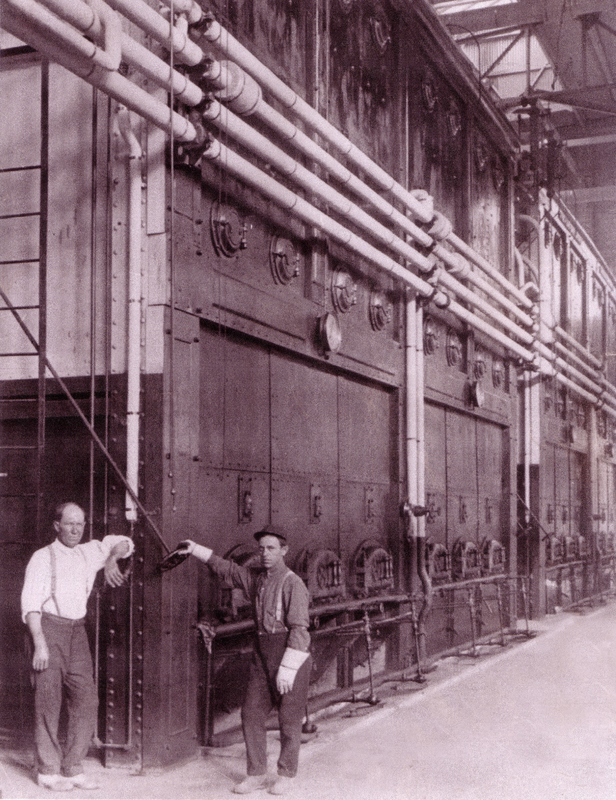

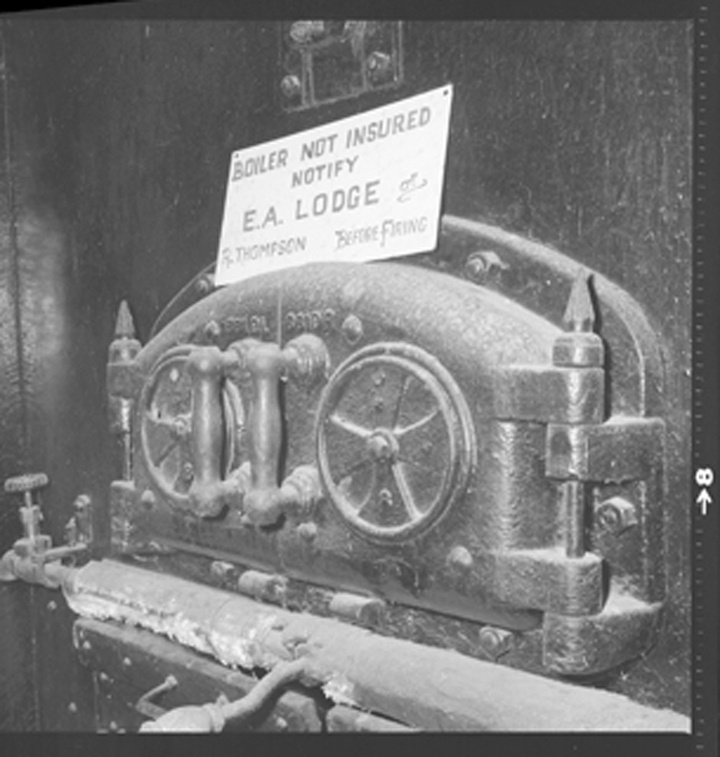

TAPCO as an auxiliary plant, more than doubled the capacity of Childs and Irving hydroelectric plants, and was able to generate 335 kilowatt hours per barrel of oil. This was unheard of at the time, making it the most efficient power plant in the world for its size. The cost to build the plant was about $600,000, approximately $13 million in today’s terms. The exceptional efficiency of the plant was achieved by four sterling boilers that burned oil to super heat filtered water being piped into the condenser from the Verde River through a 4,600 foot long concrete gravity flume that was 4 feet wide by 3 feet deep. 8,000 gallons of water were pumped per minute by two three-stage pumps located about a mile north of the plant. The rotor blades are rotated by the pressure of the steam. The rotor is connected to the turbine that in turn rotates, and creates energy by the rapid rotation of the turbine shaft in the electric generator. It is the generator that converts the kinetic energy produced by the spinning shaft into electricity, generating 10,000 horse power. The Tapco plant ended the many power grid interruptions due to lightening, washouts, or any other number of issues due to the long transmission lines from Fossil Creek.

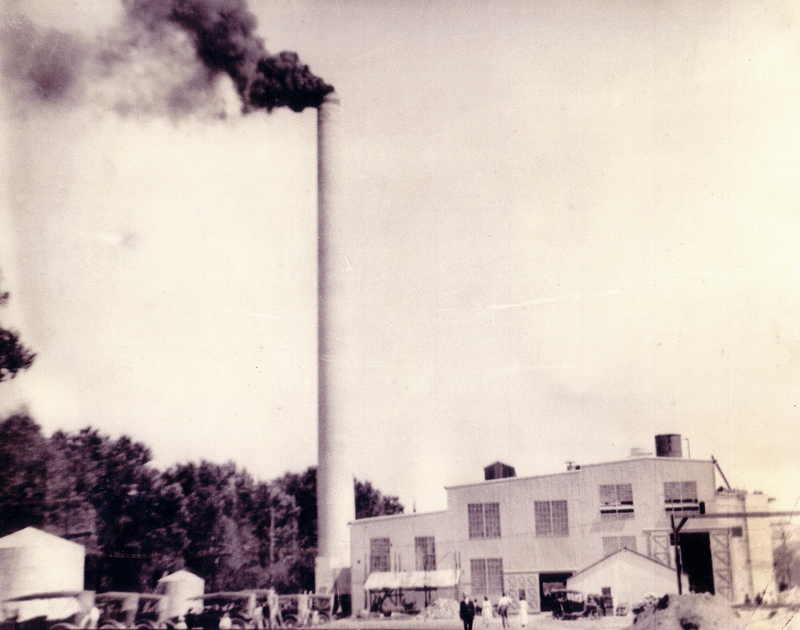

Each boiler housed burners with roughly 4,000 feet of 3 ¼” carbon steel pipe above the burners configured to convert the water to steam. The boilers exhaust was vented through a 220 foot high concrete stack that was 8 feet wide. This exhaust stack still stands today.

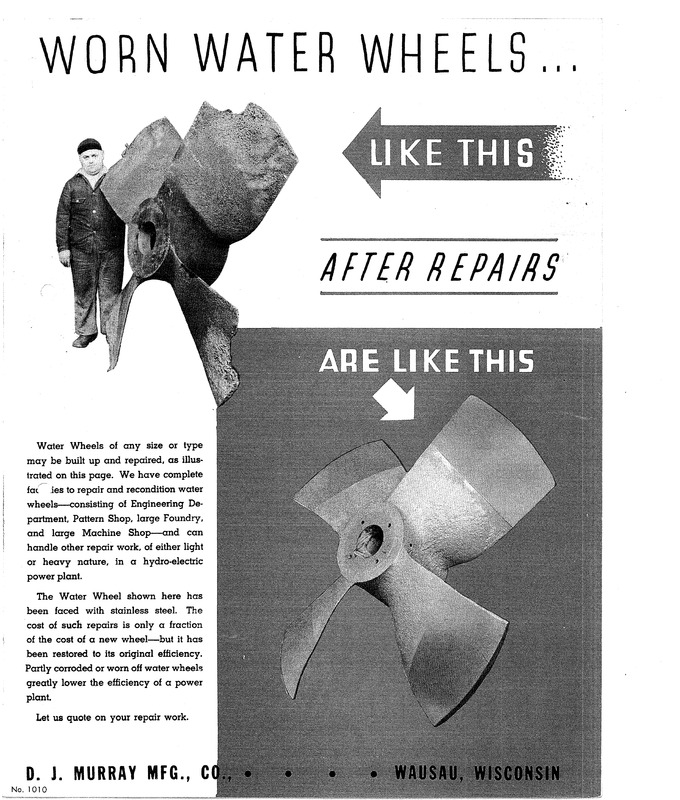

Below is an advertisment for repurpusing water wheels like the ones that were used and the Childs and Irving power plants.